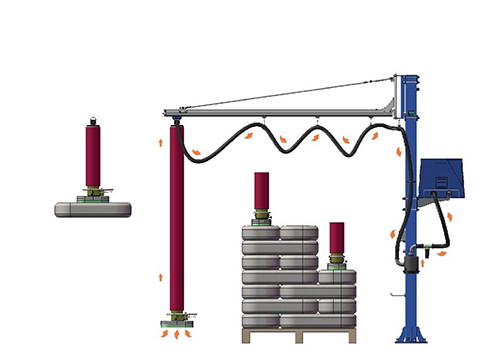

Precautions for robots and injection molding machines to be installed together

Robot and injection molding machine with the installation of machinery is currently the industry’s most cost-effective assembly line operation machinery, with its own excellent smooth operation, can improve efficiency and reduce costs.

With the factory automation equipment into the assembly line operation of the injection molding machine and robot main

equipment to stay, the installation has become a new difficulty.

Difficult point 1:

In the installation process, it is easy to appear injection molding machine direction is not uniform fault, so be sure to pay attention to maintain a sufficient safety distance, such a safety distance in the trial installation process, it is necessary to collect enough space data to ensure the success of a one-time installation.

Difficulty 2:

Injection molding machine with robot is not a very complex operation of machinery, but must be a threshold operation of machinery, which in itself requires operators to be trained before complete manipulation.

Difficulty 3:

Regular maintenance of the manipulator, you need to operate according to the instructions, many factories own private disassembly and installation will cause the machinery can not be used normally.

Difficulty 4:

In the robot work all the action can not cause obstruction to the injection molding machine machinery, as well as the surrounding facilities.

About the robot and the injection molding machine with the installation of the precautions, most of them are personnel negligence, on the basis of which will cause more losses, this point I hope the factory can reach a consensus.